Speed, quality, personalization: the new consumer demands built by robots

Industrial robotics is transforming factories and consumers alike. With defect rates near zero and personalization at scale, buyers now expect speed, flawless quality, and custom products, standards once impossible without automation.

When factories moved at the speed of people

Not long ago, factories moved at the speed of people. Human workers dominated assembly lines, limited by shift hours, mistakes, and wage costs. Building a car could take weeks, recalls were frequent, and customization was out of reach for most buyers. Consumers didn’t demand perfection because they knew the system couldn’t deliver it. Delays, defects, and limited options were simply part of the deal.

The rise of robotics

In an era where technology seamlessly blends with everyday life, industrial robotics is not just transforming factories, it's also reshaping how consumers interact with products and services. By 2025, the industrial robotics market will reach $10.2 billion, driven by labor shortages, AI integration, and the need for precision manufacturing. The automotive sector, which accounts for 30% of installations, and electronics at 27% also fuels demand for robotics. Robots now weld, solder, and package with a speed and precision no human team could match. This transformation has reshaped what consumers believe is possible.

Quality becomes non-negotiable

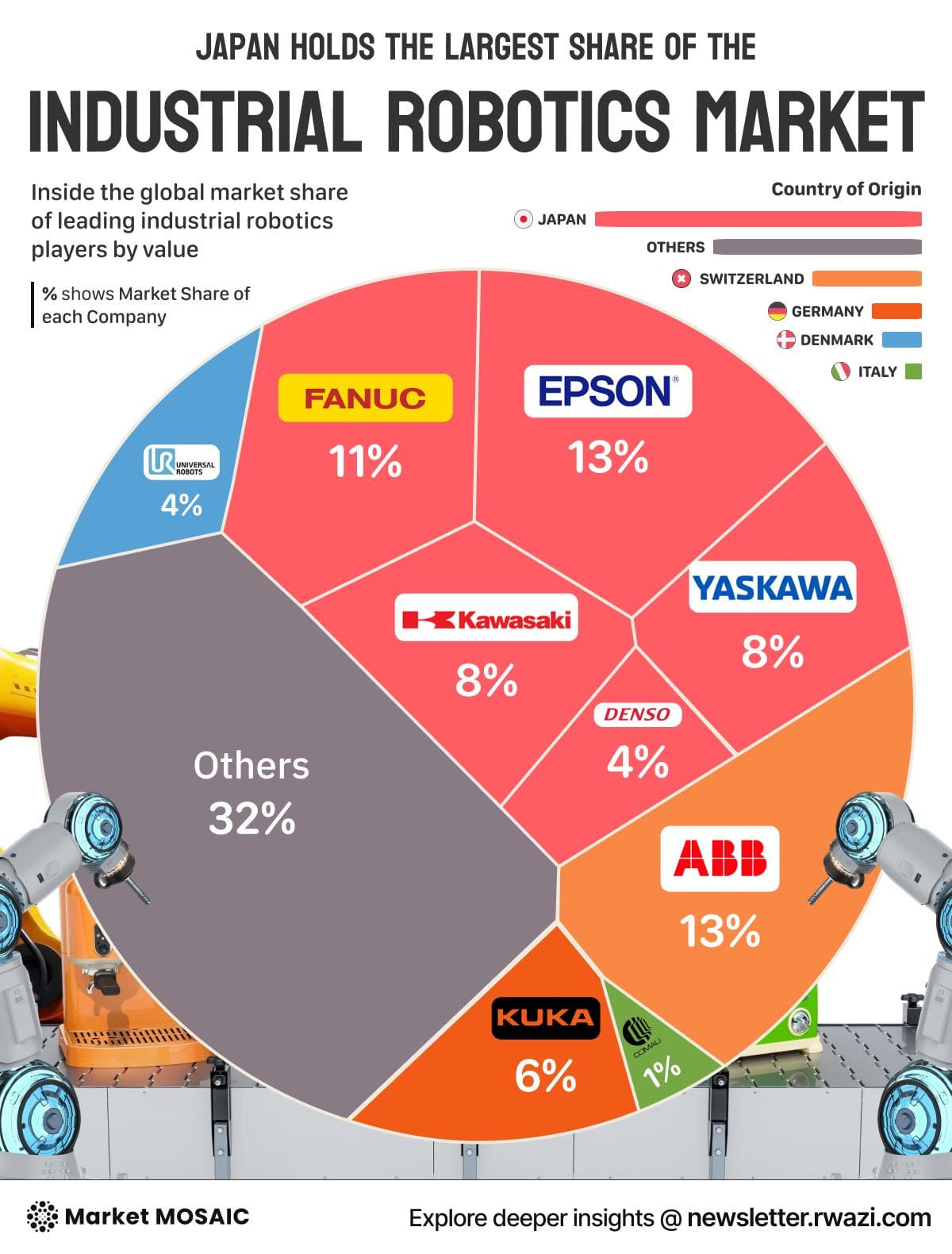

Today, 68% of buyers expect near-perfect quality, a far cry from the tolerance of the 1980s and 1990s, when recalls were common. Automation has slashed error margins from 2–3% in human-only production to under 0.1% in robotic systems. Japanese leaders; Fanuc, Epson, and Yaskawa hold a combined 32% of the market, while European firms like ABB and KUKA anchor their positions with engineering precision. The competitive race between regions is more than corporate strategy, it’s setting new global standards for what consumers accept as “normal.”

From standardization to personalization

The before-and-after story is stark. Manufacturing without robots meant standardized products, slow delivery, and expensive personalization. Today, 47% of consumers are willing to pay premiums for tailored products, because automation makes customization cost-effective at scale. Sneakers designed to a runner’s stride, cars configured down to the stitch, or electronics tuned to personal workflows are no longer luxuries, they are increasingly expected. What once seemed aspirational is becoming accessible.

The trade-Offs of automation

Yet the promise comes with trade-offs. Industrial robots cost between $50,000 and $150,000 per unit, not including maintenance, software, and training. Smaller firms often struggle to absorb these expenses. The human toll is equally real: automation has displaced thousands of factory workers, especially in textiles, electronics, and automotive. And the efficiency that robots deliver can also become a weakness. Over-automated systems are harder to adapt when supply chains falter, as the COVID-19 disruptions revealed. For consumers, mass customization can even feel impersonal if not paired with thoughtful design.

Lessons for business leaders

For business leaders, robotics is no longer a back-end decision about productivity rather it is a front-end strategy for winning markets. Competing only on cost is outdated. The opportunity lies in using automation to deliver speed, flawless quality, and personalization at scale. The firms that succeed will be those that balance efficiency with flexibility, and automation with consumer experiences that still feel human.

Manufacturing without robots meant waiting longer, settling for less, and tolerating flaws. Manufacturing with robots has reset expectations: faster, better, more personal. The challenge for business is how to turn automation into meaningful value. Done right, robots don’t just build products, they build trust.

The new standard is quality without compromise, speed without delay, and personalization without premium pricing.